The Evolution of Pigments and Dyes: Enhancing Aesthetics and Functionality

Pigments and dyes have been integral to human culture for thousands of years, serving as the primary means of adding color to materials ranging from textiles and artworks to ceramics and cosmetics. However, the role of these colorants has expanded significantly over time, especially with advancements in the specialty chemicals industry. Today, pigments and dyes are not just about adding color; they are about enhancing both aesthetics and functionality across various industries, including textiles, coatings, and plastics. Evolution of pigments and dyes reflects the growing demand for innovative solutions that meet the complex needs of modern consumers and manufacturers.

A Historical Perspective: From Natural to Synthetic

The use of pigments and dyes dates back to ancient civilizations. Early humans utilized natural sources like plants, minerals, and insects to create vibrant colors. For example, indigo, derived from the indigo plant, was a prized dye in ancient Egypt and India, while ochre, a naturally occurring pigment, was used in prehistoric cave paintings.

The industrial revolution marked a significant turning point in the history of pigments and dyes. The discovery of synthetic dyes in the mid-19th century, beginning with William Henry Perkin’s accidental creation of mauveine, revolutionized the industry. Synthetic dyes were more vibrant, consistent, and easier to produce on a large scale compared to their natural counterparts. This breakthrough led to an explosion of new colors and the widespread use of synthetic dyes in textiles and other industries.

Modern Advancements: Beyond Color

In the 20th and 21st centuries, the specialty chemicals industry has continued to innovate, leading to the development of pigments and dyes that offer more than just color. These modern formulations are designed to enhance the functionality of products, meeting the specific needs of various industries.

One of the most significant advancements in pigments is the development of high-performance pigments (HPPs). These pigments are engineered to offer superior durability, lightfastness, and chemical resistance, making them ideal for applications in harsh environments. For instance, in the coatings industry, HPPs are used to produce automotive paints that maintain their color and gloss despite prolonged exposure to sunlight, heat, and chemicals. Similarly, in the plastics industry, HPPs ensure that colored plastics retain their appearance and structural integrity, even when subjected to extreme conditions.

In addition to HPPs, the development of functional dyes has opened up new possibilities for enhancing the performance of materials. For example, UV-absorbing dyes are now widely used in textiles to protect fabrics from fading and degradation caused by exposure to sunlight. These dyes not only preserve the color of the fabric but also extend its lifespan, offering both aesthetic and functional benefits.

Another exciting development is the use of pigments and dyes in the creation of smart materials. Thermochromic and photochromic dyes, which change color in response to temperature or light, are being used in a variety of innovative applications. For instance, these dyes are employed in smart packaging, where the color change can indicate the freshness of food products or provide visual cues about the product’s condition.

At Reade, we source a variety of inorganic compounds essential to producing high-performance pigments and functional dyes, offering our clients the ability to innovate across industries with materials that are reliable and sustainable, such as Cobalt Oxide, Barium Sulfate, Amorphous Carbons, Iron Chromite, Copper Carbonate, Copper Oxide, and Iron Oxide.

Environmental Considerations: A Sustainable Future

As the specialty chemicals industry continues to evolve, there is an increasing focus on sustainability. The environmental impact of pigments and dyes has been a significant concern, particularly in the textile industry, where dyeing processes can consume large amounts of water and generate harmful effluents. In response, manufacturers are developing eco-friendly dyes and pigments that reduce environmental harm without compromising performance.

One approach is the use of water-based pigments and dyes, which eliminate the need for toxic solvents and reduce water pollution. Additionally, advances in dyeing technology, such as digital printing, allow for precise application of dyes with minimal waste, further reducing the environmental footprint of textile production.

In the coatings industry, sustainable pigments are being developed to meet growing demand for environmentally friendly products. For example, bio-based pigments derived from renewable sources are being explored as alternatives to traditional synthetic pigments. These innovations are part of a broader effort to create a circular economy in the specialty chemicals industry, where materials are designed to be reused or recycled at the end of their life cycle.

At Reade, we prioritize sustainability by offering bio-based and eco-friendly materials. Our products enable manufacturers to reduce their environmental impact while maintaining high performance. Some of our offerings that align with these sustainability goals include Selenium, Bone Char, Titanium Oxide, Magnetite, and Tungsten Oxide.

Applications Across Industries

The evolution of pigments and dyes has had a profound impact on various industries. In the textile industry, the development of colorfast, UV-resistant dyes has allowed manufacturers to produce fabrics that retain their vibrancy and durability, even after repeated washing and exposure to the elements. This has opened up new possibilities for outdoor clothing and technical textiles, where performance is as important as appearance.

In the coatings industry, the use of advanced pigments has enabled the creation of paints and coatings with superior properties, such as scratch resistance, thermal insulation, and self-cleaning capabilities. These functional coatings are used in a wide range of applications, from automotive finishes to architectural coatings, where they provide both aesthetic appeal and enhanced protection.

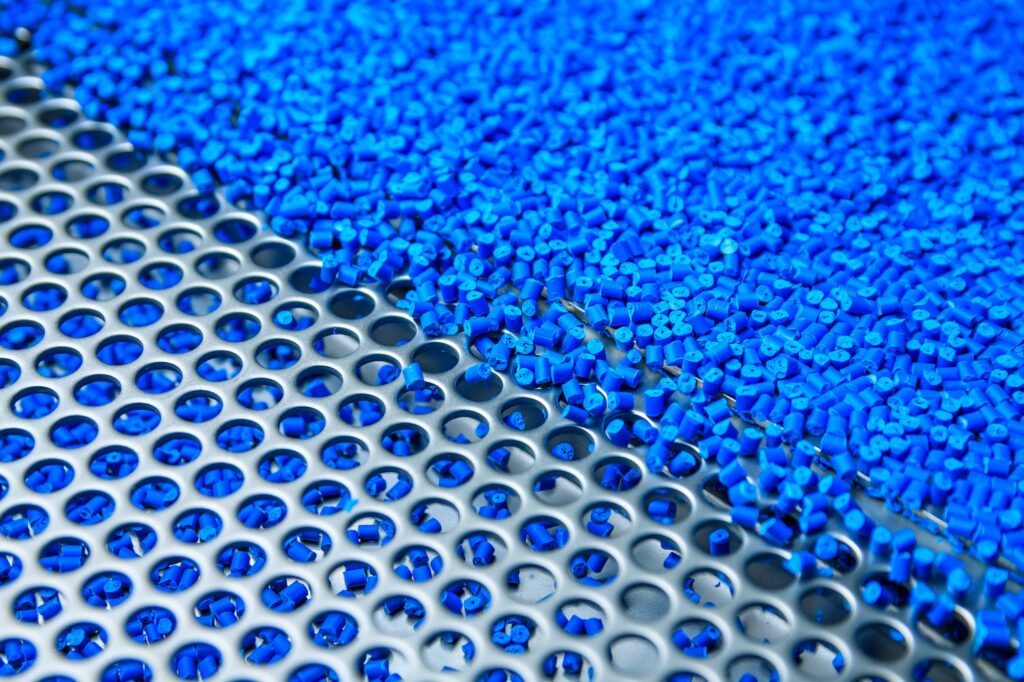

The plastics industry has also benefited from advancements in pigments and dyes. Modern colorants are designed to withstand the high temperatures and pressures of plastic processing, ensuring consistent coloration and performance in finished products. Moreover, the development of specialty pigments that provide anti-static, flame-retardant, or antimicrobial properties has expanded the range of applications for colored plastics, from consumer electronics to medical devices.

The Future of Pigments and Dyes

Looking ahead, the specialty chemicals industry will continue to push the boundaries of what pigments and dyes can achieve. The integration of nanotechnology, for instance, promises to deliver pigments with unprecedented levels of precision and functionality. Nanopigments, which are engineered at the molecular level, offer the potential for even greater durability, color intensity, and environmental compatibility.

As consumer preferences shift towards more sustainable and high-performance products, the demand for innovative pigments and dyes will only increase. Companies that invest in research and development to create next-generation colorants will be well-positioned to meet the needs of a rapidly changing market.

In conclusion, the evolution of pigments and dyes from simple colorants to advanced functional materials reflects the broader trends in the specialty chemicals industry. As these materials continue to evolve, they will play an increasingly important role in enhancing the aesthetics and functionality of products across a wide range of industries. For manufacturers and consumers alike, the future of color looks brighter—and more innovative—than ever before.