High Performance Materials

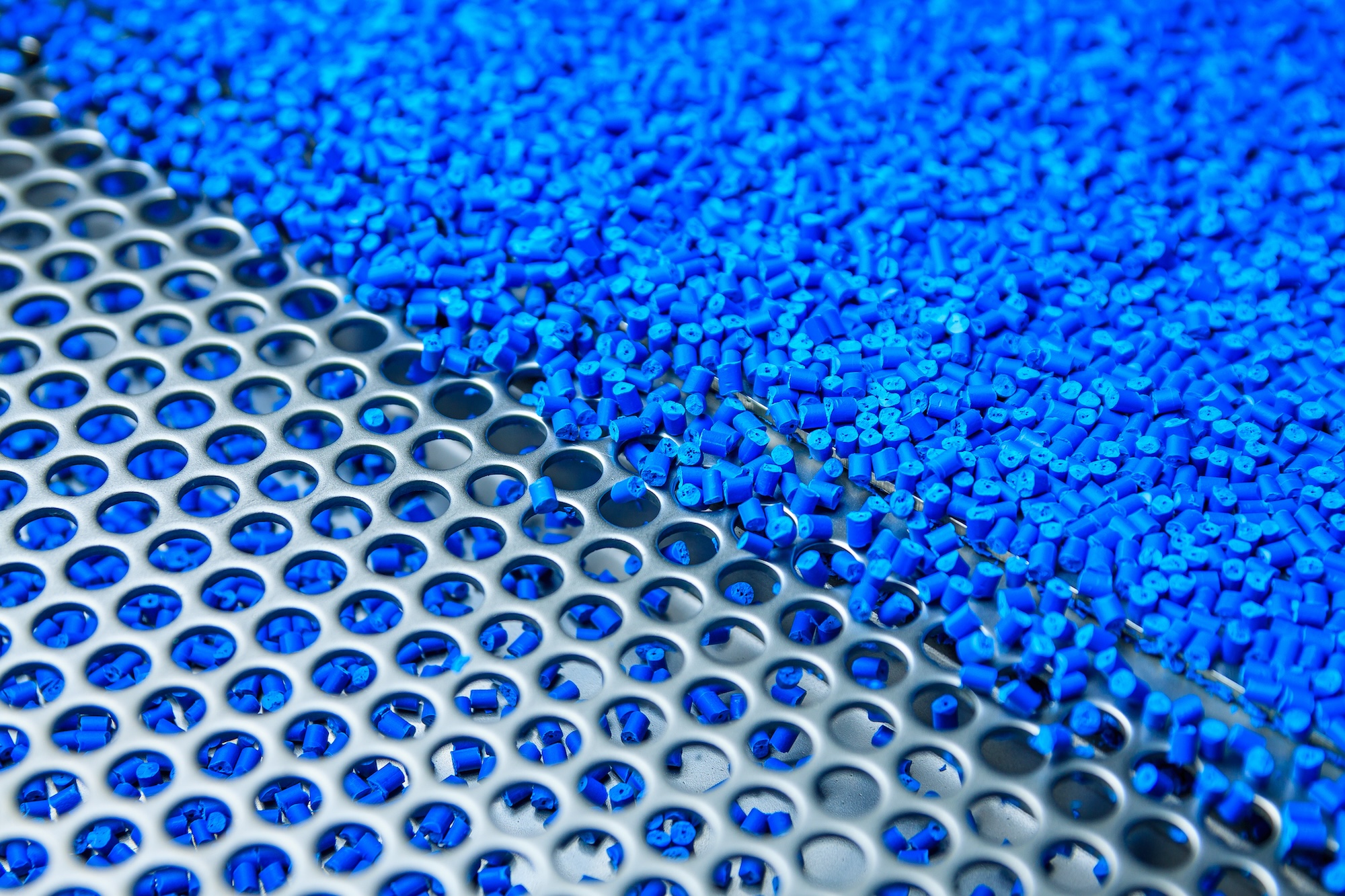

We rely on high performance materials every day, whether it’s in our cars, smoke alarms, or even the coffee maker that brewed your cup of joe this morning. We’re surrounded by them, and for the manufacturing industry, they’re a necessity for creating durable, lasting products that build consumer trust.

But what exactly are high performance materials? Are they the same as advanced materials? We’ll help demystify this category of materials and explore their possible uses across multiple industries.

WHAT ARE HIGH PERFORMANCE MATERIALS?

A high performance material is any material that greatly excels in material strength, deformation resistance, functionality, light-weighting, corrosion resistance, high-temperature capability, materials processing efficiency, sustainability and multi-functionality. The most important of those areas are shock resistance, thermal resistance, and mechanical resistance.

High performance materials can be a type of advanced material. Advanced materials are any materials whose properties have been enhanced. They are primarily found in high-technology applications such as LCD screens and fiber optics. Advanced materials is a larger group of materials that contains many more products than just high performance materials.

High performance materials span many categories of materials, but for the purposes of this article, we’ll primarily focus on metal alloys and ceramics. Both are available through Reade Advanced Materials, and our team is well versed in their applications.

HIGH PERFORMANCE METAL ALLOYS

High performance super alloys continue to be developed to solve complex manufacturing problems. Nickel super alloys are a great example of these types of high performance materials. They were developed with the aerospace industry in mind as a way to vent the extreme heat. Nickel super alloys are incredibly strong under extreme heat.

Where steel and titanium start to rapidly lose strength as they reach 50-60% of their melting temperature, nickel alloy can retain its strength level even when reaching up to 85% of its melting point. This makes it particularly well suited for the extreme environment of the inside of a jet engine.

Temperatures can reach 1,700 degrees Celsius, and extreme pressures threaten to crush any material within the turbine. That’s why most jet engines utilize exhaust blades that are grown as a singular crystal in the exact shape needed. This helps to prevent stress fractures due to mechanical force.

Magnesium aluminum alloys is another high performance super alloy with a multitude of applications. When magnesium is added to aluminum, it provides added strength, corrosion resistance, and good weldability characteristics. Magnesium aluminum is well suited for casting. It has applications as train bodies, pressure vessels, metal sheathing and scaffolding, defense vehicles, and much more.

If you’re looking for a metal alloy with an incredibly low temperature coefficient of resistance value and long term stability, manganin may be it. It’s a metal alloy trademarked by Isabellenhütte Heusler GmbH & Co. KG. made of 84.2% copper, 12.1% manganese and 3.7% nickel.

Manganin is widely used as foil and wire in resistors. In cooling systems in particular, manganin serves as an electrical conductor due to its ability to minimize heat transfer along the circuit pathway. Because it also has low strain sensitivity and high hydrostatic pressure sensitivity, it has a very niche use in gauges meant to measure concussive shockwaves.

All of these metal alloys have vastly different properties and applications, however what makes them valuable high performance materials is their ability to withstand extreme conditions while using specialized abilities to enhance the functionality of their end product.

HIGH PERFORMANCE CERAMICS AND GLASS

Ceramics can be used for a variety of uses including high temperature processing, chemical and petrochemical processing, filtration and separation, as well as mechanical applications. Ceramics are often used in the iron and steel industry as linings for metal furnaces and the tools used in smelting metals. These types of ceramics are categorized as refractories.

Titanium carbide is one of these refractory materials. It has a high melting point, hardness, mechanical strength, thermal conductivity, and corrosion resistance. Titanium carbide can most commonly be found as a coating on metal parts such as tool bits. Because of its high heat resistance, it is also used as heat shielding on space crafts for reentry into earth’s atmosphere.

Glass spheres have a different application entirely. Glass spheres are used in a variety of industries including medical, consumer goods, and in research as well. Hollow glass microspheres can also now withstand the process of injection molding. The reflective property of glass spheres is why it is incorporated into road paint and road sign faces to make them visible at night.

LEARN WHAT HIGH PERFORMANCE MATERIALS CAN DO FOR YOU

There are many specialized high performance materials with specific properties for almost any application. Reade Advanced Materials can help you navigate the process of sourcing the right material for your application to increase the value of your product. Our sales staff are experts in all of our products and will be happy to help you find exactly what you need.

ABOUT READE

As a Women Led Service-Disabled Veteran-Owned Small Business, READE supplies specialty chemical solids for nearly every industry. READE combines their roots in chemistry dating back to 1873 with supply chain expertise and customer service innovation to enable our customers to meet the needs of their manufacturing demands. With an extensive inorganic product line, READE represents over 2,000 manufacturers as a global distributor, value-added toll processor and packager.

CONTACT

Director of Marketing

Elisabeth Law, +1-401-433-7000

Elaw@reade.com